Exebenus Pulse Run your operations

The goal of digital operational procedures is to enable flawless execution and maximize operational uptime.

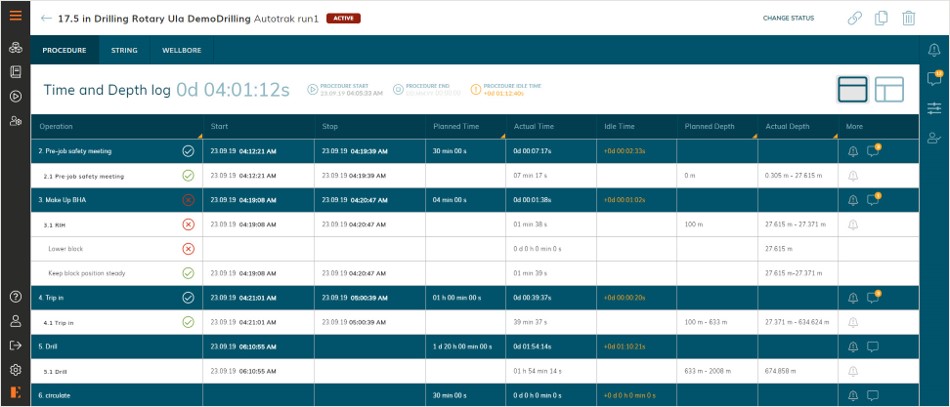

Exebenus Pulse gives all parties on the rig and in the operations center full access to real-time activity updates during execution. The operations center can transparently chat and exchange information with the rig crew as the job unfolds. Ad hoc activities can be inserted as required, and insights and best practices can be embedded for after-action review.

As real-time data flows, the system automatically recognizes and validates execution steps for one or parallel operations. It alerts the crew when operations start to deviate from plan, and when equipment limits are reached or near breach, so the execution remains within the safe operating window at all times.

- Execute with confidence.